- December 25, 2024

-

-

Loading

Loading

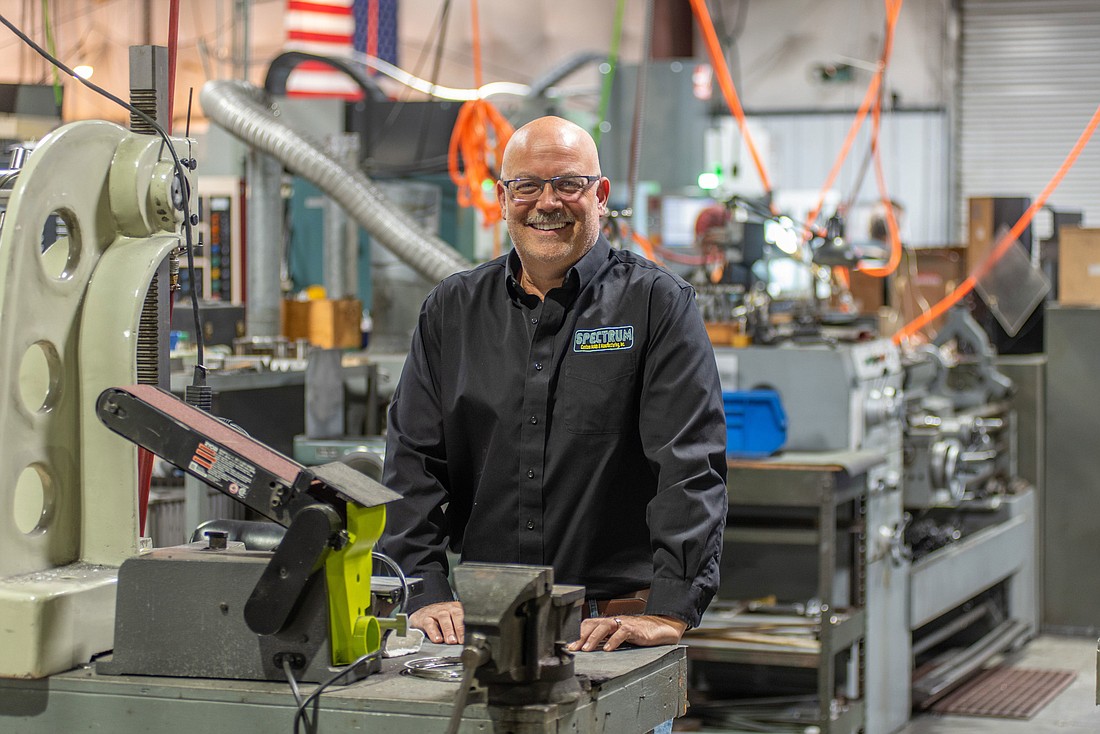

While many might think Spectrum Custom Molds & Manufacturing Inc.’s recent growth spurt came out of nowhere, the company’s owner says it’s all part of the plan.

When the owner, Mike Guidoboni bought the Bradenton-based business in January 2018, it was a small tool shop called Spectrum Custom Molds. But he purchased it with the intent to grow — and that growth has all been organic, he mentions. None of his current repeat clients are from before Guidoboni took over. Within just the first year, the company’s revenue grew 165.7%, and he expects to surpass $1 million in sales in 2021. Guidoboni paid $300,000 for the business in January 2018.

To meet the demands, and prepare for more growth, Guidoboni recently acquired the land for a new facility, which would grow its space fourfold. Currently, the company is located in a 5,800 square foot building in Bradenton, near the Sarasota Bradenton International Airport. By 2023, it plans to be in the new building at 10807 U.S. 41 just south of Port Manatee.

That space will be a 20,000 square foot building. Guidoboni paid $925,000 for the 10-acre site, in a deal that closed in June 2020. The sale transaction is under his family trust, but a tax record reflects Spectrum as the owner effective this calendar year.

After starting his career as a bridgeport operator, Guidoboni served two tours in the U.S. Army as a paratrooper. His military service plays a huge role in his current company.

For example, in addition to proudly being known as a veteran-owned and operated company, a donation of a portion of the company’s annual profits is given to a veterans' organization through its Veteran Support Give Back Program. Guidoboni recently supported fellow veteran Ken Kwiatkowski by helping refine Kwiatkowski’s invention, Grasshole, a sprinkler head protection system.

The company provides services that cover anything from product inception to delivery. Those services include:

While the growth of Spectrum was planned, not everything has gone according to schedule.

“COVID-19 has been the elephant in the room,” he says. The company, like many others in manufacturing, was challenged by having to transition quickly at the beginning of the pandemic. Guidoboni had to worry about the safety of his employees while also shifting his business model slightly. He followed CDC guidelines, and avoid shutting down,

In addition to products it was already producing, the company began developing PPE gear to stay relevant in the changing market — and support health care workers and first responders. One big example of that support? Guidoboni and the Spectrum team developed reusable elastic mask relief straps. The straps are worn on the back of the head to relieve tension compared to masks worn around the ears. The straps were donated by the company to health care workers and first responders.

Guidoboni overcame other challenges during the pandemic. The demand for cast aluminum components, for example, shifted to a demand for durable modern plastic resins. “We came up with creative ways to meet that demand,” Mike says.

The Spectrum team now provides design, material selection and prototypes to ensure customers' strength requirements are met. Once it's been approved, the company builds the injection molds and supporting tooling.

Spectrum also had a client who designed a product requiring more than 100 pounds of ABS plastic, a traditional polymer known for its rigidity and resistance. So, Spectrum redesigned its products to accommodate that. The team worked with a company in Indianapolis to develop a process of integrating CO2 pellets as a plastic additive. The result of this specific product was 30% lighter, but with the same rigidity and function.

Guidoboni has also gotten creative on the pricing side: to accommodate client demand, while also avoiding higher prices, he's been combining multiple customers' plastic requirements into single purchases. For example, the majority of clients at Spectrum purchase less than 10,000 pieces, in terms of plastic, which drives up the price. So by purchasing larger volumes of plastic, Spectrum and its clients are able to save money.

Despite all the hurdles, pandemic and otherwise, Guidoboni says he’s accomplished everything he’s set out to do with Spectrum. That’s including the replacement of older equipment. Over the past three years, he has spent over $1 million to purchase state-of-the-art equipment.

Guidoboni expects the future of Spectrum Custom Molds to be more of the same of what the past three years have been. “We’ve established our company as a well-known, one-stop, American-made shop,” he says. “We’ll continue to grow, embrace new technologies and transition based on our clients needs.”