- December 13, 2025

-

-

Loading

Loading

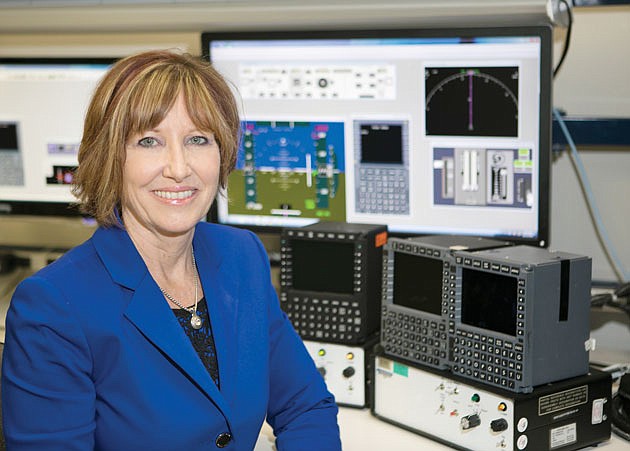

Passengers and flight crews who fly in and out of St. Pete-Clearwater International Airport depend on a vital piece of electronics that ensures they make it to their destination on time.

Few know it's made just across the street from the airport at GE Aviation.

Like car navigation devices, flight management systems (FMS) use global positioning satellites to provide precise location information for mapping software to route flights from takeoff to landing. More than 12,000 aircraft, including Boeing's 737 and the Airbus A380, use GE's flight management systems — making it one of the top-selling products built at the facility.