- November 24, 2024

-

-

Loading

Loading

Oscor Inc., a Palm Harbor company that designs and makes pacemakers and attachments, prides itself on being quicker than its giant competitors.

It does that by doing all of its work in-house, staying within its business model and keeping its corporate structure relatively flat. In contrast, its competitors rely on suppliers.

“We're extremely fast and lower cost,” says Thomas Osypka, 40, president and chief executive officer of Oscor.

One result has been 35% annual revenue increases. Oscor even expects the same boost this year, in a softer economy. People want their heart functioning property regardless of the economy.

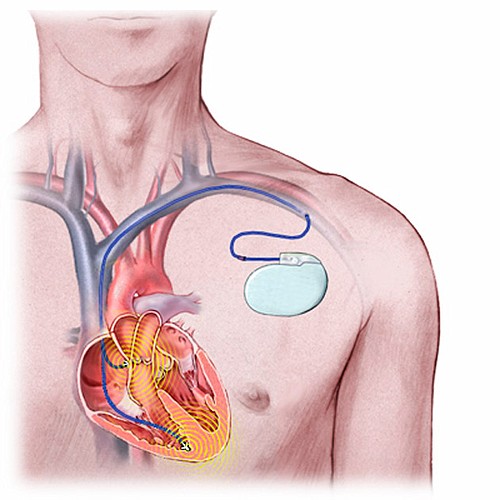

The move to outsourcing benefits Oscor because the company makes cardiac leads, or the stainless steel and titanium wires that connect the heart to the pacemaker, for other companies as well as its own brand. It is also international, selling to more than 25 countries other than the United States.

The company's product, called pacing leads, are used in connection with third-party pacemakers. Implantable and temporary pacemakers systems are used to treat people with problem hearts (an adult heart rate below 60 beats per minute) and other coronary disorders.

Oscor employs 250 people at its Palm Harbor headquarters where it also does education and training. About five years ago, it opened a production facility in the Dominican Republic that now employs 100.

Osypka's father, Peter, actually started the company in Palm Harbor in 1982 and sold it to a Swiss holding company in 1996. His son, Thomas, an engineer by trade, then bought the company back in 1999 after selling his balloon catheter company.

The company name comes from part of the name of another company his father started and the Latin word for heart, which is “cor.”

Two of the biggest challenges for Oscor have been to find good talent and to plan good products. It spends time working with new and existing employees in education and training. Its staff includes electrical and mechanical engineers and specialists in injection molding.

Research is important. Its industry requires Oscor to think three to five years ahead before doing large product development investments.

Osypka's biggest CEO lesson has been staying within the business plan and not over-promising clients.

“It's very difficult, in the medical device industry, not to take big risks and to watch cash flow,” he says. “Some of the huge companies promise everything. They are taking a huge risk. In the past, we've been very careful to make sure our decisions fit our business model.”

In the future, Osypka would like to expand Oscor into other areas of treatment such as Parkinson's Disease, urology, cancer, epilepsy and pain management. Oscor is working on disposable products and devices that can be used with very small incisions. The product would stimulate a nerve and prevent a pain impulse from traveling to the brain.

Acquiring another company is a possibility for Oscor, which purposely stayed small while many competitors merged. It is also considering partnerships or teaming with another company or organization on research. Oscor is part of the Florida Medical Device Consortium, a trade group.

Oscor has been invited to relocate to other states and cities, but the company is dedicated to Palm Harbor. Osypka, originally from Germany, moved to Florida 15 years ago after visiting Florida as a child. He met his wife here, is married and has three children.